High-precision parts enable numerous industries to maintain safety and quality standards while meeting demand and maintaining a competitive advantage. With precision parts manufacturing, you can produce versatile parts to precise specifications and enjoy a variety of benefits.

When looking to increase production output and automate capabilities, precision manufacturing is an ideal way to save time, money and materials. Understand that using precision parts manufacturing offers many benefits to various industries. Here are some of the main advantages of precision parts.

High Accuracy And Tolerance:

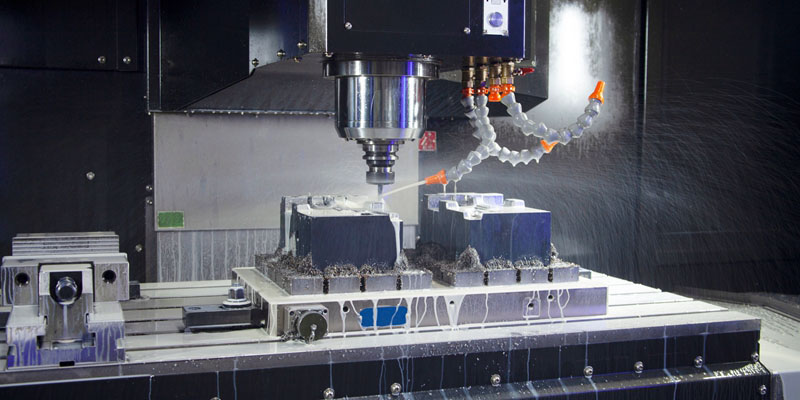

Precision CNC machining centers and similar tools can guarantee tight tolerances. Once precise specifications are entered, the automated process takes over, ensuring there is less chance of error, especially compared to manual processing. Demand for complex precision industrial parts is expected to remain strong, and even slight tolerance deviations can cause serious production problems for end customers and lead to increased costs for manufacturers.

Precision manufacturing technology allows you to produce complex parts in batches at an affordable price because there is less waste, lower labor costs, and greater part accuracy while maintaining quality and saving time.

Improve Efficiency And Reduce Lead Time

Machining tools provide precise solutions far faster than manual production. Another common advantage of choosing machine-made precision parts is the reduction of critical errors. Although you may have experienced staff operating manual workstations, since there is less automation, there is a greater risk of errors. CNC machining tools and other precision part manufacturing equipment provide better error-free results and are faster.

The automated precision machines of contemporary precision manufacturers possess incredibly advanced engineering capabilities. Precision manufacturing speeds up work that might take workers months to complete, so you can do it in just weeks. Overall, production delays are reduced and time to market shortened, so you can meet demand with confidence. This agility is essential for meeting tight project deadlines and responding quickly to market demands.

Reduce Material Waste

Producing precision parts means inevitable material waste. Creating components is a process of removing and subtracting pieces of material until what remains is the finished product. CNC precision machining minimizes material expense due to occasional human error by maximizing material utilization and minimizing waste.

Working with the right precision parts manufacturer, you can benefit from cost savings on bulk orders due to conservative material usage.

Cost Efficiency

Precision parts manufacturing is extremely cost-effective because it allows you to produce components efficiently, reduce manual labor, and achieve precise specifications quickly. It saves financial investment related to labor time, total materials and energy. With fewer errors, less production time is wasted, so you receive parts faster and don’t have to keep extra parts in stock due to potential defects and inaccuracies.

Improve Safety And Reduce Human Error

Safety and reduced human error are other great benefits for you and your employees. You can use CNC machines instead of human hands to make precision parts, ensuring the process is as safe as possible.

Switching to CNC and other machines may reduce the chance of accidents and injuries in the workplace. Workers who operate precision parts manufacturing machines often work behind guards and clear safety doors. In addition to reducing the risk of personal injury, precision machining also allows you to minimize personnel requirements or reallocate human resources. Meanwhile, CNC machines can handle the repetitive task of producing precision parts.

Improved Product Quality

Precision machining techniques, such as CNC machining, EDM, and grinding, enable the production of high-quality components with smooth surfaces and fine finishes. This manufacturing method reduces potential defects in the product and increases the opportunity for cost savings due to reduced returns and repairs due to precise measurements and precise assembly of components.

Versatile And Customization

The ideal precision parts manufacturer can produce almost any type of part you need to exact specifications in their manufacturing facility. Manufacturers can use different materials to create different parts with different applications. Ideal manufacturers can access and manufacture these products with micron-level precision through the required processes. Make sure you find a precision parts manufacturing company that has the equipment and expertise to make parts as needed.

With precision part manufacturing, you have the freedom and flexibility to design custom parts, including prototypes, and efficiently produce them to your specific needs using advanced tools like CNC centers, 3D printers, and laser cutters.

Materials Flexibility

Precision manufacturing processes support a wide range of materials, including metals, plastics, composites, and ceramics. This versatility allows manufacturers to select the most suitable material for each application, balancing factors such as strength, durability, and cost.

Easy Prototyping And Part Testing

Precision machining is a viable and smart way to explore new market opportunities and engineer potential modifications and upgrades with minimal risk. All that is required is to modify the input to a CNC or similar machine, and the device can create a new or modified design in minimal time. As a result, you can quickly develop a prototype to your specifications and test its feasibility before scaling up production.

Additionally, precision parts manufacturing companies can help you create fully functional prototypes to demonstrate your product’s capabilities. After getting feedback, you can easily change the design and retest modified prototype parts without paying for molds or castings.

Mass Production And Repeatability

Two other major benefits of using CNC and other machines to manufacture precision parts is that it is a reliable and efficient way to produce consistently high-quality parts in batches. Using precision automated machinery, you can quickly and accurately produce complex parts to standards and specifications. By improving scalability and repeatability, you can gain an edge in today’s competitive marketplace.

Scalability

Precision machining techniques are scalable to accommodate varying production volumes, from prototyping and small-batch production to high-volume manufacturing. This scalability ensures that manufacturers can adapt to changing demand and ramp up production as needed.

Consistency And Reliability

With advanced quality control measures and process monitoring, precision manufacturing ensures consistent part-to-part repeatability and reliability. This consistency is essential for maintaining product integrity and meeting regulatory requirements.

Innovation And Competitive Advantage

By leveraging precision manufacturing capabilities, companies can drive innovation, develop cutting-edge products, and gain a competitive edge in the marketplace. Precision parts enable the realization of advanced technologies and next-generation solutions across industries.

In conclusion, precision parts manufacturing offers a wide range of benefits, including high accuracy, improved product quality, enhanced performance, and cost efficiency. By leveraging advanced machining technologies and materials, manufacturers can deliver custom solutions that meet the most demanding requirements and drive innovation in their respective industries.